Blowdown Valve

Blowdown Valve, Industrial Blowdown Valve, Blowdown Valve Dealers, Blowdown Valve Distributors, Blowdown Valve Exporters, Blowdown Valve Suppliers, Blowdown Valve Manufacturers in india, Blowdown Valve Price in India

Blowdown Valves, blowdown valve boiler, blowdown valve oil and gas, blowdown valve manufacturer india, blowdown valve air compressor, blowdown valve working, continuous blowdown in boiler, Surface Blowdown Valve, Bottom Blowdown Valve, Blowdown Valves Manufacturers

isolation blow down valves, blow down gate valves, steam trap , safety blow down valves, boiler blow down valves, steam boiler blow down valves, compressorair compressor, dump blow down valves, automatic blow down valves, intermittent blow down valves, quick opening blow down valves, gestra blow down valves, spirax sarco blow down valves, parallel slide blow down valves, levcon blow down valves, gas blow down valves, rotary blow down valves, bottom blow down valves, auto blow down valves, seatless blow down valves, everlasting blow down valves, flowserve blow down valves, yarway blow down valves, audco blow down valves, purpose blow down valves, angle blow down valves, manual blow down valves, blow down valves process, swagelok blow down valves

BLOWDOWN VALVE MANUFACTURERS IN INDIA

Blowdown Valves, blowdown valve boiler, blowdown valve oil and gas, blowdown valve manufacturer india, blowdown valve air compressor, blowdown valve working, continuous blowdown in boiler, Surface Blowdown Valve, Bottom Blowdown Valve, Blowdown Valves Manufacturers

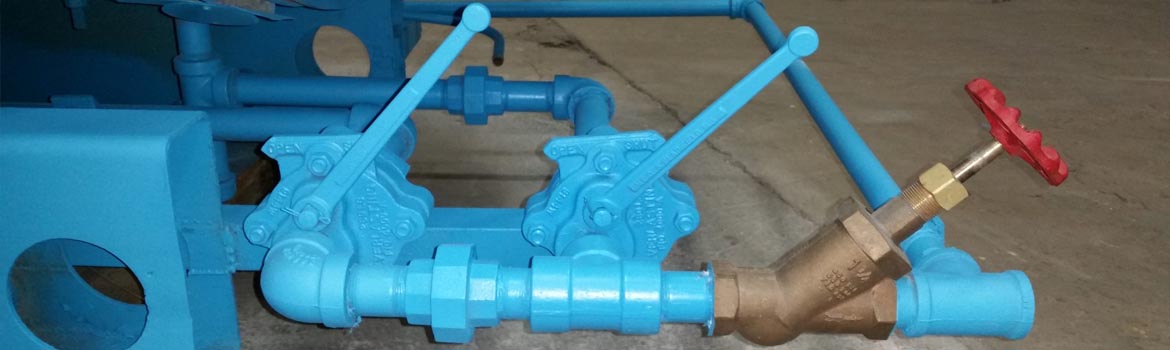

Blowdown Valves

| Materials Used | Features | Types | Uses |

The blowdown valves are a very popular category of pipe valves, used in a wide variety of applications. They are used for operation in open position. The main function of blowdown valve is mainly to control a continuous flow of steam /fluid under high differential pressure. The outstanding feature of this type of valve is that it can maintain fluid tightness and it is easily operated without the help of any wedging action.

Materials used:

- Brass

- Bronze

- Copper

- Aluminum

- Stainless steel

- Cast Iron

- Zirconium

- Nickel

- Monel etc.

Buying Tips

The blow down valve dimension must be selected according to the operating conditions. The factors to consider are:- Working Pressure

- Working Temperature

- Exhausting Capacity

- Material

- Size

- Type

- Durability

- End Connection

- End Usage

- At start-up, the valve closes. This leads the air-oil separator pressure to build up.

- At shut-down the valve opens to bleed the air-oil separator to atmosphere. This is when a pressure is applied. The valve can also be used as a by-pass valve to bleed air with the help of the compressor at start-up.

- The design and materials of blow down valves must be such as to minimize the effects of a fluid stream in conditions where water contains sometimes abrasive particles.

- The outlet of such valves is always "Venturi tube" shaped.The stem is rising non rotating.

- There is a local stroke indicator which shows the position of the disk.

- The bonnet less design of the valve helps in easy dismantling, inspection and maintenance.

Some types of blowdown valves are as follows:

- Surface blowdown valve: This is supposed to be the best choice for blowdown valves. It is used for removing dissolved solids. It helps in removing solids at those points where they are most concentrated.

- Bottom blowdown valve: This is another type of valve for controlling dissolved solids. The function of this type of valve is to remove sludge which gathers in the bottom of the boiler.

- The size of the blowdown line.

- The boiler pressure.

- The length of the blowdown line between the blowdown vessel and the boiler.

Certain uses of these valves are as follows:

- These valves are appropriate for use with air compressors.

- They are used to help in the removal of slug and unwanted materials after cleaning the pipes.

- Blow down valves are found on the water feeders.

- They are also used to lower water cut-offs.

- They can control the concentration of solids in the boiler.

Angle Pattern Single Stage and Multi stage Blowdown Valves

Unique Feature(#300 upto #2500 rating valves):

• Single piece stem and plug assembly.

• Non Rotating Stem design.

• Rising Stem non rising hand wheel .

• Roller Burnishing of Stem in Gland Packing section.

• Special designed Control Cone (SN 46)for use on high pressure reduction/Throttling applications.

• Single Stage Valve in Angle Pattern Block Body design with replaceable seat bush feature available for high pressure drop application and handling high flow.

• Multi stage Valve in Angle Pattern Block Body design with replaceable seat bush feature available for high pressure drop application and high flow.

Benefits

Advantages due to Unique Feature:

• Single piece stem and plug assembly: No vibration of plug when the valve is kept semi open position. Cracking of Stellited seat due to High frequency vibration of plug when handling high pressure drop across valve seat is a common occurrence. Can be avoided by considering this feature.

• Non Rotating along with Single Piece Stem and Plug Design feature ensures that the plug does not rotate when it sits on the valve seats. It also prevents damage to seat due to entrapped solid such as pipe scales or entrapped solid when the valve operator puts excess effort on handwheel to ensure tightness at seat.

• Non Rising Hand wheel is ideal for use in areas where space between pipes is limited.

• Roller Burnishing in Gland packing section gives a mirror finish to the spindle and helps reduce ware and tare of the gland packing. Effort required to operate the valve reduces due to reduced friction at the gland packing section due to this feature.

• Control Cone feature (SN 46) with slots machined as per the valve discharge capacity. Valve plug specially designed such that there is no real flow till the plug seating area has move a minimum of 10% of the total lift away from the valve seat. This helps to separate the seating area from the throttling of High pressure reduction area. As a result the harmful effects of cavitation and flashing do not affect the seating area of the valve enhancing the seat life .

• Replaceable seat bush feature reduces maintenance down time cost considerably.

• Need to only replace seat bush or valve stem and any other critically damaged part instead of replacing the full valve .

Specification:

• Available in Welded Bonnet for rating #1500 and #2500.

• Available in Forgings of Carbon Steel(A105).

• Sizes upto2 ½” (10mm – 65mm).

• End Connections Butt Weld , Socket Weld, Flanged End (ANSI /DIN) available as standard. Special Flange connections offered against request.

• Can be offered with Electrical Actuators.

• Angle Pattern Design (Inlet and outlet at right angles to each other).

• Offered with IBR Certificate Format III-C when offered for Steam Service.

Boiler Blowdown Valve Specifications

Quick Opening and Slow Opening

| Seats and Discs | Rating 250 integral, 300 and 600 Hard Stainless Steel |

| Body Material | Rating 250 Cast Iron, 300 and 600 Carbon Steel |

| Connections | Screwed or Flanged |

| Operators | Lever, Handwheel |

| Configurations | Straight Through Flow Two-Way, Angle, or Wye Patterns |

| Unitandem Body | Quick and Slow Opening—2 Slow or 2 Quick Valves in One |

Sizes

- 1” through 2 ½”

Pressure

- ASME/ANSI Class 250, 300 and 600

Construction

- Cast Iron or Carbon Steel

End Connections

- Screw Ends or Flanged

Actuation

- Lever or Hand Wheel