NRV Check Valve

Check Valve, Industrial Check Valve, Check Valves Dealers, Check Valves Distributors, Check Valves Exporters, Check Valves Suppliers, Check Valve Manufacturers in india, Check Valves Price in India

Non-return Check Valve, Industrial Non-return Check Valve, Non-return Check Valves Dealers, Non-return Check Valves Distributors, Non-return Check Valves Exporters, Non-return Check Valves Suppliers, Non-return Check Valve Manufacturers in india, Non-return Check Valves Price in India

Swinging Check Valve, Tilting Disc Check Valve, Piston Check Valve, Non slam Check Valve, Needle Check Valve, Nozzle Check Valve, gf wafer check valve, Swing Check Valve, Duel Plate Check Valve, Wafer Type Check Valve (Plate Type), Disc Check Valve, Flap Type Check Valve, Forged Steel Lift Check Valve, swing check valve class 900, check valve 10000 psi, check valve 30000 psi, check valve 60000 psi, check valve 15000 psi, check valves for water, check valves price list, check valve 5 psi, check valve 30 inch, check valve 300#, check valve 300#, check valve 600#, check valve 900#, check valve class 900, check valve 1 inch, check valve 2 inch, check valve 1/2 inch, check valve 1/4 inch, check valve 4 inch, check valve 15mm, wafer check valve class 900

CHECK VALVES MANUFACTURERS IN INDIA

Check Valves

Function:

Non-return Check Valve or one-way Check Valve is a mechanical device, a valve, which normally allows fluid (liquid or gas) to flow through it in one direction only.

Operation:

Operation:

- The main mission of a Check Valve is to avoid back pressure in the process (avoid that the flow is switching direction)

- A Check Valve can also be used for isolation purpose.

- There will normally be regulations telling how many and in which location Check Valves are to be installed in the process.

Design:

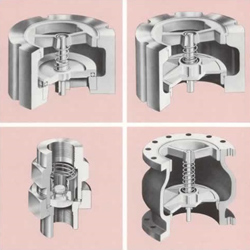

- As for most valves there are a lot of different designs of Check Valves. The basic design is a Duo Check Valve with two discs mounted on an hinge pin in the center of the Check Valve. The Check Valve has a standby closed position with springs pushing the discs towards the seats. These valves are designed for installation on a horizontal line where the hinge pin is placed in a vertical position.

- To reduce space and weight these Check Valves are often delivered as wafer valves.

Advantages:

- Self closing check valve

- Self cleaning design

- Integrated spring for horizontal installation

- Optimized flow design

- Corrosion resistant and high pressure rating

- Wide selection of material for best chemical resistance

- Optional screen assembly protects against dirt

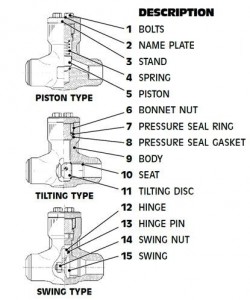

Other types of Check Valves:

- Swinging Check Valve

- Tilting Disc Check Valve

- Piston Check Valve

- Non slam Check Valve

- Needle Check Valve

- Nozzle Check Valve

Swing Check Valves

Bolted Cover Design, Flanged End

Suitable For Horizontal & Vertical Line

J.D. Check Valves [NRV] are Swing Type and Bolted cover Construction. The one piece disc construction is securely fastened to the hinge by means of a lock nut & pin. The Disc is free to rotating type to avoid any other wear. The hinge pin offers excellent wear resistance properties.

Swing Check valves also can be supplied with Titling disc design, Dash pot arrangement and outside lever & weight design for use where control of the disc is desires.

J. D. Controls also offer P.T.F.E. (PFA / FEP) Lined Ball Type/Y Type & Rubber Lined Flap Type Check Valves for high corrosive application.

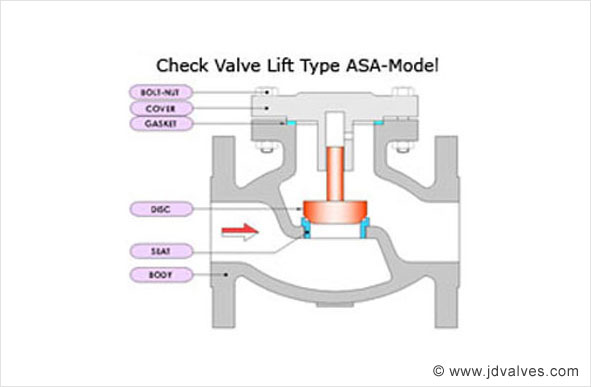

Lift Type Check Valve [Non Return Valve] - ASA Body Design Lift Type Check Valve [Non Return Valve] - ASA Body DesignBolted Cover, Suitable for Horizontal Line Only Design Standard: BS 1868 / DIN Size Range - 1" to 12" Pressure Rating - 125# / 150# / 300# End Connection : Flanged End |

![Lift Type Check Valve [Non Return Valve]](images/check-valves/lift_type_check_valve1.jpg) Lift Type Check Valve [Non Return Valve] Lift Type Check Valve [Non Return Valve]Bolted Cover, Suitable for Horizontal Line Only Design Standard: BS 1868 / DIN Size Range - 1" to 12" Pressure Rating: PN 6 / PN 10 / PN 16 / PN 25 / PN 40 End Connection : Flanged End |

![Swing Type Check Valve [Non Return Valve]](images/check-valves/swing_type_check_valve1.jpg) Swing Type Check Valve [Non Return Valve] Swing Type Check Valve [Non Return Valve]Bolted Cover, Suitable for Horizontal & Vertical Line Design Standard: BS 1868 Size Range - 1" to 12" Pressure Rating - 125# / 150# / 300# End Connection : Flanged End |

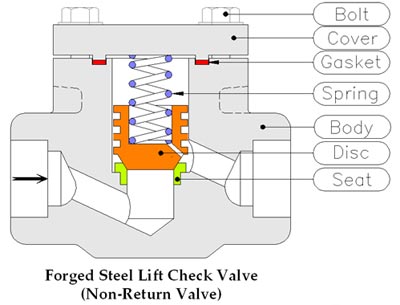

Forged Steel Lift Check Valve (Non Return Valve) Forged Steel Lift Check Valve (Non Return Valve)Bolted Cover Type Design Standard: BS 5352 Pressure Rating: 800# / 1500# End Connection : Screwed / Socket Weld / Butt Weld End |

Salient Features :

|

Material of Construction:

| Cast Iron | : IS 210 Gr FG 200 |

| Cast Carbon Steel | : ASTM A 216 Gr WCB |

| Cast Stainless Steel | : ASTM A 351 Gr CF 8/CF 8M |

| Forged Carbon Steel | : ASTM A 105 |

| Forged Stainless Steel | : ASTM A 182 Gr F304 / F316 |

| Design Type | : Swing Type Disc / Piston Lift Type Disc |

| End Connection | : Screwed AS PER BSP/BSPT/NPT |

| Socketweld | : AS PER ANSI B 16.11 |

| Flanged | : AS PER ANSI B 16.5 |

| Pressure Rating | : ASA 125#, 150#, 300#, 600#, 800#, PN 16 & PN 40 |

| Engineering Option | : Gear Operated, Electrical Actuated, |

| Size Range | : 15mm to 300 mm |

Design & Testing International Standard:

| Valve Design | : BS 5351 / ANSI B 16.34 / API 6D |

| Pressure Testing | : BS 6755-I |

| Face To Face | : ANSI B 16.10 |

| Flange Drilling | : ANSI B 16.5 / BS 10 Table / DIN / IS 6392 |

| Butt Weld End | : ANSI B 16.25 |

| Socket Weld End | : ANSI B 16.11 |

| Screwed End | : ANSI B 1.20.1(BSP/NPT) |

Types of Check Valves: Swing Check Valves

Swing check valves feature a simple design complete with a disc attached to a hinge at the top. As fluid passes through, the valve remains open. When a reverse flow occurs, the changes in motion as well as gravity help to bring down the disc, effectively closing the valve.

Swing check valves feature a simple design complete with a disc attached to a hinge at the top. As fluid passes through, the valve remains open. When a reverse flow occurs, the changes in motion as well as gravity help to bring down the disc, effectively closing the valve.

These types of check valves are commonly used for firefighting and flood prevention in sewage systems. They’re also designed to work with materials such as gas, liquids, and other types of media.

Types of Check Valves: Stop-Check Valves

Stop-check valves can be used for many applications. They’re designed to start, stop, and regulate the flow of materials, and they help to prevent backflow.

If pressure in the system is too low, these valves will automatically close to prevent reverse flow. As a result, damage usually caused by backflow is prevented.

These types of check valves also work with an external mechanism or an override control. With these, you can set the valve to close regardless of flow direction or pressure to ensure safety and efficient operations.

These types of check valves also work with an external mechanism or an override control. With these, you can set the valve to close regardless of flow direction or pressure to ensure safety and efficient operations.

Generally, stop-check valves are used in power plants and boiler systems. They’re also beneficial for petroleum production and refining, hydrocarbon processing, and high-pressure safety services.

Types of Check Valves: Ball Check Valves

Unlike other valves, ball check valves use a spherical ball inside their bodies to help control the flow direction in pipes and systems. This ball rotates freely when fluid passes through the system, which causes a wiping motion and even wear between the ball and seat. According to Valve Magazine, this unique action makes ball check valves ideal for systems working with viscous materials.

If pressure decreases or reverse flow is detected, the ball will move toward the seat. This creates a seal and helps to maintain the appropriate direction of fluid flow.

Ball check valves are one of the most common valves available. Industrial systems as well as common household items use them. In fact, The Valve Pipeline states that ball check valves can be found in liquid or gel mini-pump dispenser spigots, spray devices, and manual air pumps.

On top of that, ball check valves are used for metering pumps and chromatography pumps as well.

Types of Check Valves: Silent Check Valves

Silent check valves are incredibly useful for water pipelines and systems. These valves are engineered to control and protect against pressure surges that can occur in water lines. They also work to prevent water hammer and reverse flow.

Silent check valves are constructed with a spring-assisted disc. When fluid pressure in the valve is higher than the cracking pressure, or the pressure needed open or close the valve, the spring lowers the disc to prevent reverse flow.

The valve is also manufactured to include a guide to keep the disc moving in a vertical. This allows it to reseat properly

SILENT CHECK VALVES

These unique CPV valves control hazardous pressure surges and water hammer far more effectively than traditional swing check valves. A specially engineered stainless steel helical spring initiates instant closing at zero flow velocity. Since swing check valves do not close until reverse flow begins, pressure surges are never allowed to build. CPV Silent Check Valves are available with precision machined metal-to-metal seats for general service or soft seats for bubble tight sealing to 250°F (121°C).

Silent Check Valves are available in a wide variety of styles and materials, in sizes from ½” NPT to 24″ flanged and pressure ratings from 125 to 2500 psi.

CPV Silent Check Valves are ideal for applications like heating systems and condensate return lines with pressures to 300 psi. They come with a soft seated closure disc as standard to 250°F (121°C). A stainless steel disc can be substituted if anticipated temperatures are up to 350°F (177°C). Other available options include the use of bronze for the body, union nut and tail piece; a stainless steel guide, retaining ring and spring (Catalog 36), steel body and stainless steel disc (Catalog 34) or all stainless steel, type 18-8 (Catalog 37) Sizes are from ½” to 2″ NPT.

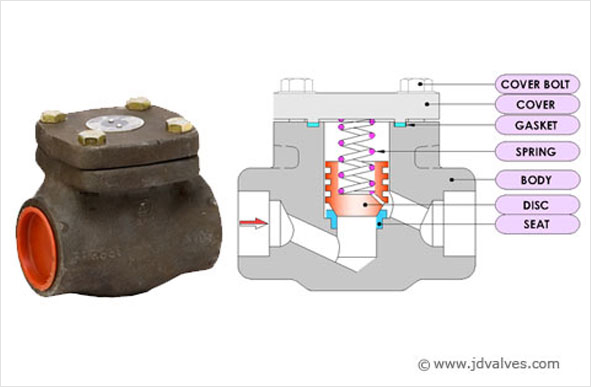

Hani Enterprises Metals Forged Steel Check Valves are manufactured as per BS-5352 Standard and Tested to BS-5146 Standard. Hani Enterprises Metals designed piston type lift check valve incorporating self-cushioning effect.

Body Guided piston assuring accurate return to seat ring to achieve leak tightness.

Hani Enterprises Metals Forged Steel Lift Check valves are available under any Third party inspection.

|

|

Forged Carbon Steel Check Valve

Socket Weld End Connection

Size: ¾” (DN 20)

Design & Testing International Standard :

Valve Design |

BS 5352 |

Pressure Testing |

BS 5146 |

Face To Face |

ANSI B 16.10 |

Butt Weld End (Welded Neck) |

ANSI B 16.25 |

Socket Weld End |

ANSI B 16.11 |

Screwed End |

ANSI B 1.20.1(BSP/NPT) |

Salient Features :

A Compact But Extremely Sturdy Design for High Pressure & Temperature Service |

Bolted Cover Design |

Piston Type Body Guide Disc |

Assure Perfect Alignment of Disc & Seat Ring |

Material of Construction :

| Body & Cover | Disc & Seat |

ASTM A 105 (Forged Carbon Steel) |

AISI 410 (S.S. 410 – 13% Cr. Steel) |

ASTM A 182 F 304 / 304L (Forged Stainless Steel 304 / 304L) |

AISI 304 (S.S. 304) |

| ASTM A 182 F 316 / 316L (Forged Stainless Steel 316 / 316L) | AISI 316 (S.S. 316) |

ASTM A 182 F 11 / F 22 (Forged Alloy Steel) |

AISI 304L (S.S. 304L) |

| AISI 316L (S.S. 316L) | |

| Stellited Hard Face on Seat & Disc |

Options :

Other Material of Construction |

Flanged End, Flange Welded to Body, Rating 150# / 300# / 600# |

Butt Weld (Welded Neck) / Socket Weld / Screwed (BSP/NPT) Connection |

Seat & Disc Stellited Hard Face |

Special Trims on Request |

Applications :

Power Plants & Process Industries |

Fertilizers Plants |

Sugar Industries & Distillery Plants |

Water, Steam, Gas, Oil & other Non-aggressive media |

Other application on request |

Please specify below details at the time of enquiries/orders:

Types of Valve |

Flow Medium (Service) |

| Pressure Rating Class | Design Pressure |

Valve Size |

Operating (Working) Pressure |

Type of End Connection |

Design Temperature |

Material of Construction |

Operating (Working) Temperature |

Trims Materials |

|

Wide Range of Industrial Check Valve

- Cast Iron Check Valve (Non Return Valve)

- Cast Carbon Steel Check Valve (Non Return Valve)

- Cast Stainless Steel Check Valve (Non Return Valve)

- Forged Steel Check Valve (Non Return Valve)

- Alloy Steel Check Valve (Non Return Valve)

- Alloy 20 Check Valve (Non Return Valve)

- High Pressure Check Valve (Non Return Valve)

- Swing Check Valve (Non Return Valve)

- Wafer Type Check Valve (Non Return Valve)

- Disc Check Valve (Non Return Valve)

- Lift Type Check Valve (Non Return Valve)

- Single Disc Check Valve (Non Return Valve)

- Rubber lined Check Valve (Non Return Valve)

- P.T.F.E. lined Check Valve (Non Return Valve)

- Non-Slam Type Check Valve (Non Return Valve)

- Zero Leakage Check Valve (Non Return Valve)