Butterfly Valve

Butterfly Valves Dealers, Butterfly Valves Distributors, Butterfly Valves Suppliers, Butterfly Valves Manufacturers , Butterfly Valves Price in India

butterfly valve bs 5155, butterfly valve bs en 593, wafer butterfly valve, lug butterfly valve, flanged butterfly valve, double flanged butterfly valve, flanged butterfly valve dimensions, single flange butterfly valve, double flanged butterfly valve dimensions, double flanged valve, butterfly valve manufacturers, butterfly valve types

4 butterfly valve dimensions, butterfly valve function, butterfly valve specification, dn400 butterfly valve, Pneumatic Operated Butterfly Valves, butterfly valve 150 psi, butterfly valve 200 psi, butterfly valve 250 psi, butterfly valve 300 psi, butterfly valve 300 lbs, butterfly valve 150 lb, butterfly valve 600 lb, butterfly valve ansi 150, butterfly valve ansi 300, 4 inch butterfly valve, butterfly valve 40 inch, butterfly valve 40mm, butterfly valve 400mm, butterfly valve 50mm, 700 mm butterfly valve

Table of Content

- -----> Wafer Type Butterfly Valves

- -----> Lug Type Butterfly Valves

BUTTERFLY VALVE

A Butterfly Valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disc. Operation is similar to that of a Ball Valve, which allows for quick shut off. Butterfly Valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required.

Hani Enterprises Wafer Type Butterfly Valve have been developed with extensive application, design and manufacturing expertise.Our High Performance Slim-Seal, Concentric design Butterfly Valves are reliable, maintenance free shutoff with permanently gas-tight seal with an integrally moulded or replaceable elastomer body liner. In our Butterfly Valve Wafer Body Design we are providing two nos. flange locating holes for sizes up to 12 and from size 14 and above 04 nos. for easy alignment of valve during installation. Flange locating hole confirm to as per ANSI B 16.5 Class 125 & Class 150 / BS 10 Table D, E, F / PN 6, PN 10, PN 16 or other international standard. We are also providing High performance Butterfly Valves with Full-Lugs type body design with raised faces and flanged ends connection, Double Flanged Centric Disc Rubber lined Butterfly Valves, Seatless Butterfly Dampers.

Our Slim Seal design Butterfly Valves body seat mechanism have a very low torque, tight shut off with zero leakage, compact actuator selection, and long life smooth easy operation. The slim-seal, center disc design valves are widely available with different combination of body, seat & disc materials to satisfy the need of most industrial application.

Specifications of Butterfly Valves

- Valve Design : Wafer Type Butterfly Valves/ Lug Type Butterfly Valves/ High Performance Butterfly Valves / Seatless Butterfly Damper / Double Flanged Centric Disc Butterfly Valves / Double Flanged Valves

- Operations : Lever Operated / Gear Operated / Electrical / Pneumatic / Hydraulic Actuator

- Mounting Pad /Top Flange Drilling : As per ISO 5211 Part II

Butterfly Valve – Specifications

| DESIGN | Wafer |

| TYPE | Soft Seated Offset- Series 230

Metal To Metal- Series 240 Sleeved- Series 250 |

| SIZE | 50 to 900 mm (2” to 36”) |

| RATING | 150# |

| FLOW CHARACTERISTIC. | Throttling, On-Off. |

| MATERIALS BODY | Cast Iron, Carbon Steel, Stainless Steel etc. |

| VANE | Carbon Steel ,Stainless Steel. |

| BODY SLEEVE | Neoprene, Nitrile, PTFE, EPDM, Silicon, Butyl, Viton etc. |

| SOFT SEAT | PTFE. |

| GLAND PACKING | PTFE V Rings upto 180° C

Grafoil upto 400° C. |

| ACTUATOR FORM | Diaphragm, Rotary, Electric. |

| ACTUATOR TYPE | Scotch |

| DIAPHRAGM | Nitrile / Neoprene |

| SPRING RANGE | 3 – 15 Psig (0.2 – 1.0 Kg/cm²)

6 – 30 Psig (0.4 – 2.0 Kg/cm²) |

| AIR SUPPLY | 20 – 35 Psig (1.4 – 2.5 Kg/cm²) |

| AIR CONNECTION | 1/ 4” or 1/ 2” NPT |

| ACCESSORIES OPTIONAL | Valve Positioner – Pneumatic, Electro Pneumatic, Smart, Airset, Solenoid Valve, Air Lock, Volume Booster Limit Switches- Micro/Proximity with Dome Indicator. Top or Side Mounted Handwheel Limit Stops |

Butterfly Valve – Design Features

- Compact & simple design, low cost and maintenance free.

- Very high Cv to body size ratio.

- Reliable smooth operation and flow control with assured product quality.

- Bubble tight shut off, leakage Class – VI.

- Rangeability of 33:1 in the control range.

- Flow characteristic throttling for modulating duty.

- Choice of Replaceable Linear/Moulded Lining.

Quality And Performance Guarantee

- Produced with Quality Systems accredited to ISO 9001: 2008 by Bureau Veritas.

- Full material certification available for all major component Parts.

- Full guarantee on design and Performance.

- All testing are performed to the requirements of ANSI B16.34.

Salient Features of Butterfly Valves

- Concentric, Slim-Seal Design

- Greater Sealing Capacity

- Soft Seat Design and Wafer Design

- Lower Torque with any fluid

- Permanently tight closure

- Bi-Directional Valve

- Optimum operation under Vacuum Condition

- Suitable for On-off as well as Throttling Service

- Materials for almost all media

- Short Face To Face Dimension

- Long Service Life, Smooth and Easy Operation

- Maintenance Free Version

- Less Weight, Easy To Install

Special Options for Butterfly Valves

- Off Set Disc Design Butterfly Valve for high pressure & temperature service.

- Moulded / Replaceable Seat option

- Gear / Pneumatic Rotary Actuator Operated

- P.T.F.E. (PFA/FEP) Lined Butterfly Valve

- Flanged End, Butterfly Valve

- Damper Type Butterfly Valve for High Temperature Air Service

- Off Set Disc Design Butterfly Valve for high pressure & temperature service

- Tailor Made Valve

Application

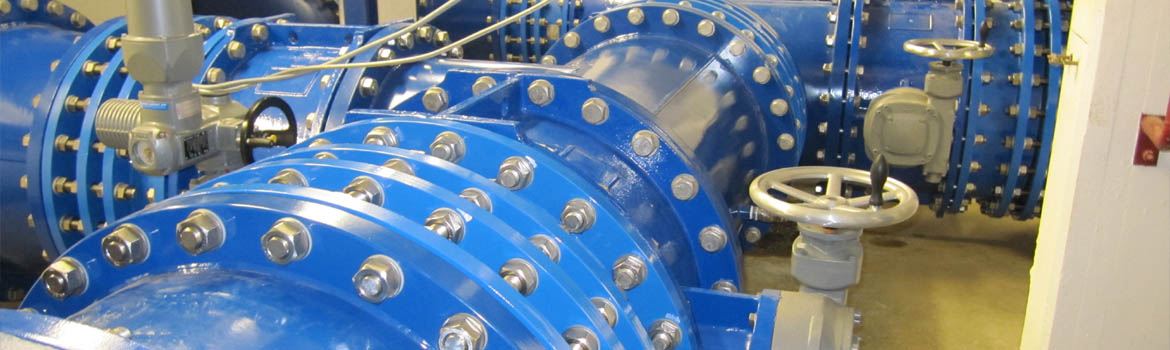

- Water Treatment Plant

- Paper Industry

- Sugar Industry

- Breweries

- Chemical Industry

- Waste Effluent Treatment Plant

- Drilling Rigs

- Gas Plant

- Cooling Water Circulation

- Heating & Air Conditioning

- Pneumatic Conveyors

- Compressed Air

Wafer Type Butterfly Valves

General Purpose Rubber Lined Butterfly Valves

Hani Enterprises Butterfly Valves are designed to meet the demanding requirements of the general utility valve market with the HVAC segment in particular. Our Butterfly valve incorporates the optimum design features to provide long trouble free service in the field. This general purpose soft seated Butterfly valve has a fully rubber lined single piece body with centric disc construction and is available in wafer type body pattern.

The body liner which also functions as the soft seat, comes in either a replaceable version or an integrally molded (bonded) version and offers 100 % bi-directional sealing against vacuum to rated pressure of PN 10 or PN 16.The wafer style body has universal design to fit between pipe flanges of almost all popular flange standards.

Our Butterfly Valves are generally supplied with manual hand lever or gear operated, depending on valve size. We are also offering Butterfly Valves with either Pneumatic, Hydraulic or Electrical actuator operated for automation as per clients requirement.

WAFER TYPE BUTTERFLY |

INVESTMENT CASTING WAFER |

WAFER TYPE BUTTERFLY |

NYLON COATED DISC BUTTERFLY VALVE AS PER ISO MOUTING PAD EASY TO MOUNT ACTUATOR, GEAR BOX |

WAFER TYPE GEAR OPERATED |

Technical Specifications

- Valve Type : Centric Disc Design Butterfly valve with a single piece Rubber lined body

- Body Type : Short Wafer

- Seat Type : Replaceable for sizes 50 NB to 600 NB , PN 10 rating. Bonded seat for sizes 40 to 1200 NB for all applicable ratings.

- End Connection : Wafer sandwiched

- Size Range : 40 NB to 1200 NB

- Pressure Rating : 40 NB to 600 NB-PN16 (maximum) , 650 NB to 1200 NB-PN10 (maximum)

- Operating Temperature Range : -500 C to 2000 C (depending on MOC)

- Seat Leakage : Tight Shut Off

- Operation : Lever / Gear operated, Pneumatic/ Hydraulic/ Electrical Actuator operated

Conformity Codes and Standard

Design and Manufacturing Standard : API 609 category A/BS 5155/MSS SP-67

Testing Standard : BS 6755-I / API 598

Face to Face : Short wafer as per ISO 5752 Tab 5 & API 609 category A

Top Flange Drilling : ISO 5211 part II

Flange standard conformity : ANSI 150, DIN PN6 / PN10 /PN16 , JIS 5K / 10K / 16K BS 10 Tab D & E, IS 6392 NP 0.6 / 1.0 / 1.6 For sizes 650 ANSI B 16.47 Class 150 Series A / BS 3293 Class 150 and Series B / API 605

Material Of Construction

- Body : CI / SGI / WCB / CF8 / CF8M

- Disc : SGI / WCB / CF8 / CF8M

- Seat : EPDM / Viton / Nitrile / Neoprene / Hypalon / Silicon

- Shaft : AISI410 / SS 316 SH

Standard Test

- Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

- Seat Test: 1.5 times the working pressure with water.

- Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

- Special Test: On request, any other test can be carried out according to special instruction by client.

Key Features Of Wafer Type Butterfly Valve

- Unique triple sealing system for shaft sealing, eliminates any fugitive emission or secondary leakage.

- Self lubricated PTFE lined bearings for both drive end and non-drive end shaft ensures minimum bearing friction torque.

- Seat liner extending on to the flange contact faces, eliminates the need for separate flange gaskets during installation.

- Controlled compression of the gasket face to offer optimum sealing & prevent gasket face crushing failure.

- Bi-directional valve with tight shut off sealing capability to hold vacuum to rated pressure in either direction.

- Excellent adaptability for actuated operation through standardized top flange mounting dimensions for actuator fitment.

- Suitability for ON /OFF as well as throttling duties.

- Choice of seat and disc materials to suit media conditions and service requirements.

- Adaptability to fit between companion flanges of all popular flange standards for the wafer style body.

- Possibility of lower seat rating to obtain reduced operating torque and extended seat life for low operating pressures.

Lug Type Butterfly Valves

General Purpose Rubber Lined Butterfly Valves

Hani Enterprises Lug Type Butterfly valve incorporates the optimum design features to provide long trouble free service in the field. This general purpose soft seated Butterfly valve has a fully rubber lined single piece body with a centric disc construction and is available in wafer lugged style body pattern to ensure precise location in pipeline.

The body liner which also functions as the soft seat, come either in a replaceable version or an integrally molded (bonded) version and offers 100 % bi-directional sealing against vacuum to rated pressures of PN 10 or PN 16. The lugged version with threaded holes can be used as end of line valves or terminal end valves.

Our Butterfly Valves are generally supplied with manual hand lever or gear operated, depending on valve size. We are also offering Butterfly Valves with either Pneumatic, Hydraulic or Electrical actuator operated for automation as per clients requirement.

Standard Test

- Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

- Seat Test: 1.5 times the working pressure with water.

- Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

- Special Test: On request, any other test can be carried out according to special instruction by client.

LUG TYPE BUTTERFLY VALVE |

LUG TYPE GEAR OPERATED BUTTERFLY VALVE |

Technical Specifications

- Valve Type : Centric Disc Design Butterfly valve with a single piece Rubber lined body

- Body Type : Wafer Lugged

- Seat Type : Replaceable for sizes 50 NB to 600 NB , PN 10 rating. Bonded seat for sizes 40 to 1200 NB for all applicable ratings.

- End Connection : Wafer Lugged

- Size Range : 40 NB to 1200 NB

- Pressure Rating : 40 NB to 600 NB-PN16 (maximum) , 650 NB to 1200 NB-PN10 (maximum)

- Operating Temperature Range : -500 C to 2000 C (depending on MOC)

- Seat Leakage : Tight Shut Off

- Operation : Lever / Gear operated, Pneumatic/ Hydraulic/ Electrical Actuator operated

Conformity Codes and Standard

Design and Manufacturing Standard : API 609 category A/BS 5155/MSS SP-67

Testing Standard : BS 6755-I / API 598

Face to Face : Short wafer lugged as per ISO 5752 Tab 5 & API 609 category A

Top Flange Drilling : ISO 5211 part II

Flange standard conformity : ANSI 150, DIN PN6 / PN10 /PN16 , JIS 5K / 10K / 16K BS 10 Tab D & E, IS 6392 NP 0.6 / 1.0 / 1.6 For sizes 650 ANSI B 16.47 Class 150 Series A / BS 3293 Class 150 and Series B / API 605

Material Of Construction

- Body : CI / SGI / WCB / CF8 / CF8M

- Disc : SGI / WCB / CF8 / CF8M

- Seat : EPDM / Viton / Nitrile / Neoprene / Hypalon / Silicon

- Shaft : AISI410 / SS 316 SH

Key Features Of Lug Type Butterfly Valve

- Unique triple sealing system for shaft sealing, eliminates any fugitive emission or secondary leakage.

- Self lubricated PTFE lined bearings for both drive end and non-drive end shaft ensures minimum bearing friction torque.

- Seat liner extending on to the flange contact faces, eliminates the need for separate flange gaskets during installation.

- Controlled compression of the gasket face to offer optimum sealing & prevent gasket face crushing failure.

- Bi-directional valve with tight shut off sealing capability to hold vacuum to rated pressure in either direction.

- Excellent adaptability for actuated operation through standardised top flange mounting dimensions for actuator fitment.

- Suitability for ON /OFF as well as throttling duties.

- Choice of seat and disc materials to suit media conditions and service requirements.

- The lugged wafer pattern ensures precise self centering of valve between mating flanges.

- Possibility of lower seat rating to obtain reduced operating torque and extended seat life for low operating pressures.